Description

Reinforced Strength You Can Trust: J-B Weld Cold Steel Epoxy

When durability and long-lasting performance matter, professionals and DIYers alike turn to J-B Weld cold steel epoxy. The 8265S formula is one of the brand’s most trusted and versatile products — a steel-reinforced, two-part epoxy designed for bonding and repairing a wide range of materials under tough conditions.

Whether you’re sealing cracks in metal piping, bonding broken tools, or doing automotive repairs, this epoxy offers industrial-strength adhesion that hardens to a steel-like finish.

🔧 What’s Included in the Package

-

1 x 1 oz tube of epoxy resin

-

1 x 1 oz tube of hardener

-

Clear mixing instructions

-

Total volume: 2 oz

This convenient set gives you precise control and enough material for multiple medium-sized repair jobs.

🧩 Key Features

-

Sets in 4–6 hours, full cure in 15–24 hours

-

Steel-reinforced formula: cures to a dark grey, metallic finish

-

High strength bond up to 5020 PSI

-

Resistant to water, heat, chemicals, and shock

-

Suitable for use on metal, plastic, PVC, wood, fiberglass, ceramic, tile, and more

-

After curing, it can be drilled, tapped, machined, sanded, or painted

🛠 Ideal Applications

The J-B Weld cold steel epoxy is designed for:

-

Automotive repairs (engine blocks, transmissions, metal housings)

-

Household appliances and fixtures

-

Plumbing pipes and fittings

-

Metal furniture and tools

-

Industrial machine parts

-

Hobby and craft projects

It’s perfect when you need a permanent, heavy-duty bond that can endure stress, vibration, and exposure to elements.

🛠 How to Use J-B Weld Cold Steel Epoxy

-

Prepare the Surface: Clean and dry the bonding area. Roughen the surface with sandpaper for best results.

-

Mix the Two Parts: Use equal amounts of the resin and hardener. Mix thoroughly on a disposable surface.

-

Apply the Mixture: Use a spatula or applicator to spread it evenly across the repair area.

-

Let it Set: Leave undisturbed for 4–6 hours. Full cure occurs in 15–24 hours.

-

Finish: Once cured, the epoxy can be shaped, sanded, or painted as needed.

⭐ Customer Reviews

“Used it on a cracked aluminum bike frame. Two years later, still holding strong.”

— Rafael G., Oregon

“I sealed a leak in my radiator tank with this stuff. It’s amazing how strong it gets.”

— Jenna M., Ohio

🔁 Compare with Other J-B Weld Products

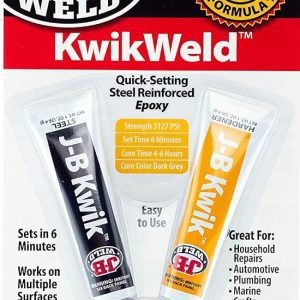

J-B Weld 8265S is ideal for general-purpose, structural bonding. If you need quicker curing, consider J-B Weld KwikWeld, which sets in 6 minutes. For high heat, check out J-B Weld ExtremeHeat.

View our full product? Browse Now

Or read more technical specs on J-B Weld’s official site

🧪 Chemical & Safety Info

-

Non-toxic when cured

-

Clean up uncured epoxy with acetone or citrus-based cleaner

-

Use gloves and apply in a well-ventilated area

-

Keep out of reach of children

🗃 Storage & Shelf Life

Store tubes in a dry, cool environment with caps tightly sealed. Unused product can last up to 2–3 years when stored properly.

Pro Tips for Maximum Bonding Strength

To get the most reliable results from J-B Weld cold steel epoxy, follow these expert tips:

-

Temperature matters: Ideal application temperature is between 50°F and 90°F (10°C to 32°C). Cold weather may slow curing, while extreme heat may affect bond strength.

-

Mix thoroughly: Be sure to mix the resin and hardener until the color is uniform. Incomplete mixing can result in weak bonding or failure.

-

Clamp when possible: If you’re bonding two flat surfaces, use clamps or a heavy object to hold them together during the curing process for an even stronger seal.

-

For vertical applications, use masking tape to hold the epoxy in place as it sets.

These small steps ensure you get the most out of the product’s strength and reliability — whether for automotive fixes, home repairs, or industrial use.

✅ Final Thoughts

Whether you’re making professional repairs or tackling your next home improvement project, the J-B Weld cold steel epoxy delivers exceptional strength and versatility. With a tough steel-reinforced formula and broad material compatibility, it’s your go-to solution for permanent, worry-free bonding.